How is it done? The latest soccer shoes Nike GS

Nike GS or Green Speed - football shoes new generation. Nike GS - the fastest, lightest, most technologically advanced shoes that Nike has ever made.

Unique synthetic material Kanga-Lite, which is made from the top, provides the perfect touch of the ball, and specially arranged spikes allow to distribute the load so that the shoes responsive to every movement of the players.

When creating GS recyclable materials were used to make Nike GS environmentally friendly .

When creating GS recyclable materials were used to make Nike GS environmentally friendly .

Today we know where and how to build this football shoes.

See also: Football in the mud , soccer match between Denmark and Germany pornographic actress , Top 10 most expensive players of Euro 2012

(Total 32 photos)

1. Complete description of all components of the boots.

2. Top manufactured from a material mixture consisting of 50% and 50% castor plastic.

3. Sock completely made from castor beans.

4. Laces, tongue and lining are made of 70% recycled materials.

5.

6. Compound top and sock.

7.

8. Fixing form.

9. Final product.

10.

11.

12.

13. The famous logo - "stroke", symbolizing the wing of the goddess Nike in front of the factory. The factory is located in the small Italian town of Montebelluna that a 40-minute drive from Venice.

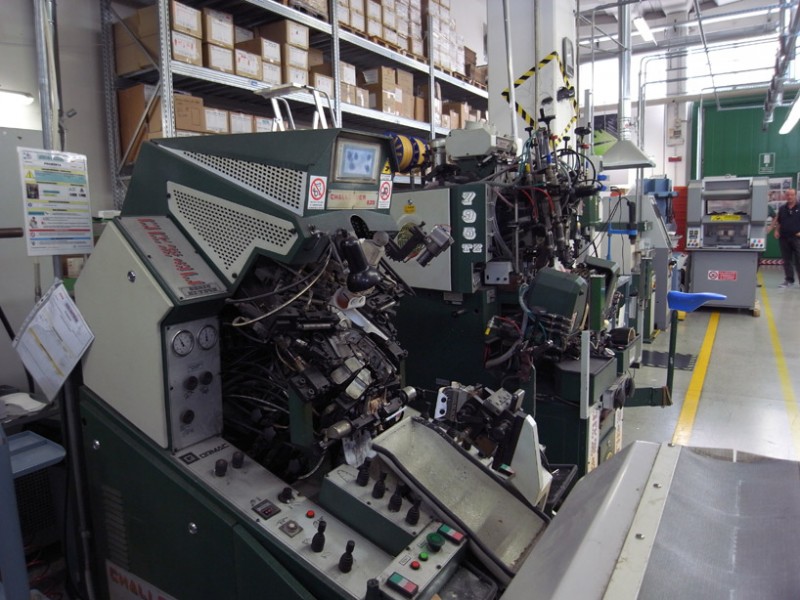

14. The entire production is located in a rather compact shop.

15. Place where special mixtures are prepared that are used in production.

16. Working boots on the creation of a team of 15 people.

17. Rack with blocks and complete models.

18. Factory often conduct tours.

19. Modules for making soles.

20. It uses only renewable energy, recyclable and renewable materials.

21. Industrial sewing machine with which shoes cause various flags and logos.

22. Packaged and labeled finished products.

23. On one of the machines you can see the poster with the player. Working in a factory is not just workers, but football fans.

24.

25.

26.

27.

28.

29.

30.

31. Stickers remind that the workers must be very careful with this powerful equipment.

32. Showcase with production plant in the lobby.